Ventilation systems may be indispensable in everyday life, but they are also the source of a great deal of noise pollution. And in sectors such as industry, they contribute directly to the creation of a permanent background noise that can quickly become distressing for employees. Faced with this problem, companies have long relied on silencers for ventilation systems. But how do these systems work, and what are their limitations? Vibiscus tells you all about it in this article.

Traditional silencers for ventilation systems

Traditional silencers for ventilation systems are designed to attenuate the noise transmitted by the air inside ducts. Their principle is usually based on passive sound absorption. They are made of porous or fibrous materials, arranged to capture sound energy as it passes through them. By dissipating this energy in the form of heat, the sound level at the duct outlet is reduced.

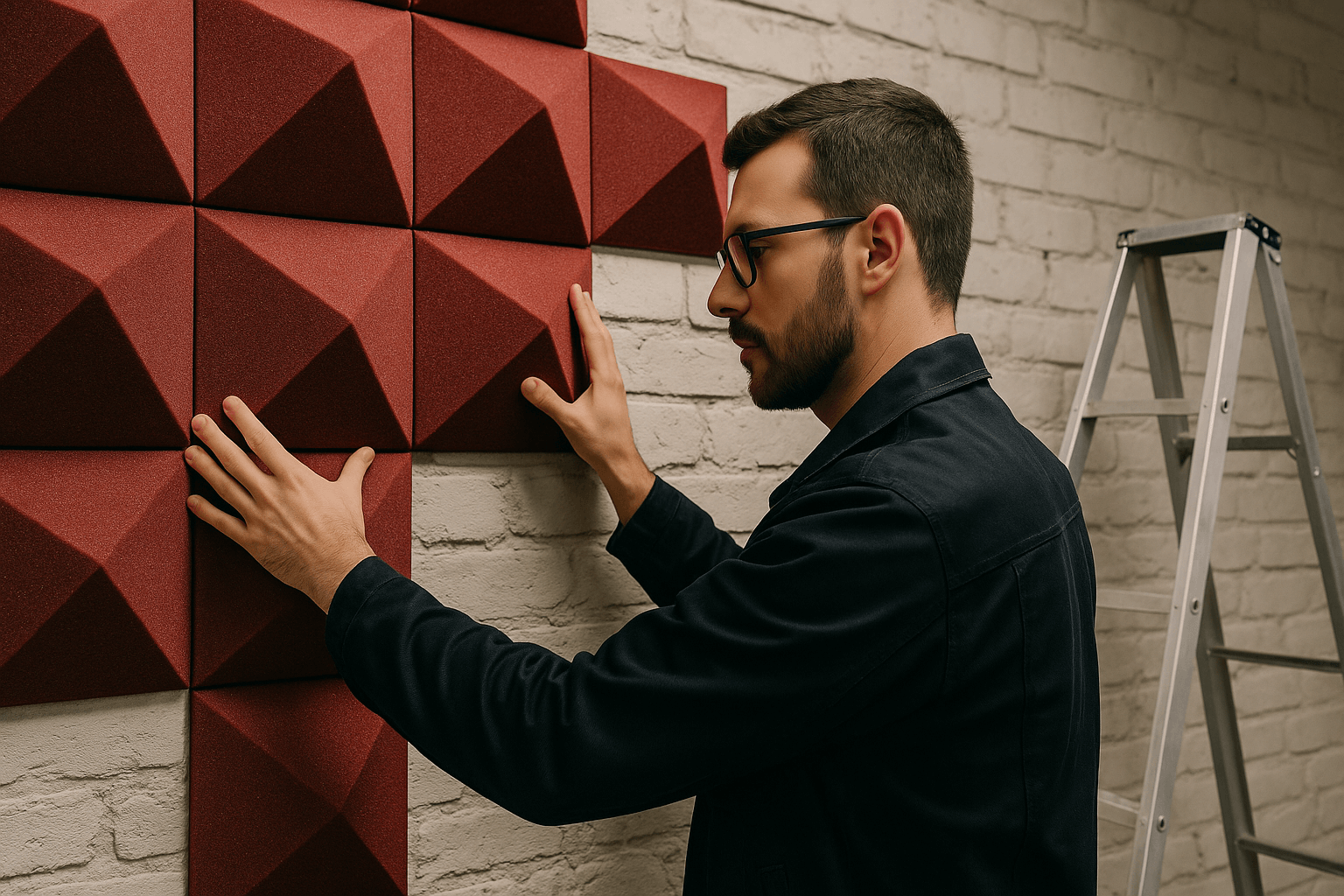

In industry, these silencers take the form of rectangular or cylindrical modules, installed in line in ventilation networks or in the immediate vicinity of noise sources such as fans or air handling units. Their effectiveness depends on several parameters: the length of the silencer, the thickness and nature of the absorbent materials, and the frequency range to be treated.

The advantage of these solutions is that they are relatively simple to implement and well known to design offices. They effectively reduce certain noise components, particularly in the mid- and high-frequency ranges, and are still suitable for many standard applications.

The limits of traditional solutions

Despite their widespread use, traditional silencers for ventilation systems have structural limitations that are becoming increasingly apparent in modern industrial environments. The first concerns their spectral efficiency. The noise generated by ventilation systems is rich in low frequencies. Passive sound-absorbing materials are much less effective in these frequency ranges, unless the volume of the silencer is considerably increased.

This volume constraint quickly becomes a problem. In existing installations or constrained buildings, the space available in the ducts is limited. Installing a longer or thicker silencer becomes difficult, if not impossible, without profoundly modifying the network architecture.

Traditional silencers can also have a significant impact on airflow performance. By introducing additional resistance to air flow, they generate pressure losses. This can sometimes mean oversizing fans or increasing their rotation speed, which can paradoxically recreate noise and increase energy consumption.

Finally, these solutions remain fixed. Once installed, their acoustic properties do not adapt to variations in system operation. In industry, ventilation regimes are constantly changing, depending on processes, schedules and outdoor conditions. A silencer designed for a specific operating point may be less effective in other configurations.

A modern alternative with Vibiscus

Faced with the limitations of traditional silencers for ventilation systems, Vibiscus offers a radically different approach to noise reduction. Rather than relying solely on passive materials, Vibiscus technology lies at the crossroads of classical acoustics and intelligent systems.

The heart of our innovation is a network of microphones and moving membranes integrated directly into the device. These elements modify the acoustic properties of the surrounding air in real time. The absorbent surface thus created is no longer static: it becomes configurable and adaptable to the specific needs of each installation.

Unlike traditional Active Noise Control (ANC) systems, Vibiscus doesn’t add sound to mask existing noise. Instead, it acts as a “boosted” acoustic material, capable of absorbing and dissipating sound energy much more effectively, even at low frequencies.

The compactness and modularity of the Vibiscus system enable it to be integrated into a wide variety of ventilation ducts, including existing networks. Our technology adapts to complex geometries and constrained industrial environments, where traditional silencers quickly reach their limits.

Frequently asked questions

Yes, in certain simple, well-dimensioned cases, they remain effective. However, as soon as the constraints of space, low frequencies or speed variability appear, their limits become obvious.

Yes, it has been designed to fit into demanding industrial environments, with high flow rates, complex geometries and severe acoustic constraints.

This is one of its major assets. Its compact, modular design enables seamless integration into existing ventilation networks, without the need for major modifications.

In addition to improving acoustic comfort, Vibiscus contributes to greater energy efficiency, optimized airflow management and a lasting reduction in noise pollution.

At a time when acoustic requirements are increasing and the overall performance of HVAC systems is becoming a strategic issue, traditional silencers are showing their limits. Innovative solutions like the one developed by Vibiscus open up a new path: that of smarter, more adaptable noise reduction, better aligned with contemporary industrial realities.

Want to take advantage of our technology? Contact us to discuss your needs.