In today’s industrial environments, noise is one of the most underestimated pollutants. Beyond being a source of discomfort, excessive sound exposure can reduce productivity, affect workers’ health, and even compromise the performance of sensitive equipment. Regulations across Europe and worldwide are becoming increasingly strict, requiring companies to adopt effective and sustainable solutions to limit noise propagation. This is where the concept of an industrial sound trap comes into play. While conventional silencers and absorbers have long been used, they often fail to address the complexity of modern installations, where airflow, geometry, and acoustic frequencies vary greatly. Vibiscus introduces a new way of thinking about noise control combining adaptability, precision, and advanced acoustic engineering.

An industrial sound trap is a device designed to reduce noise generated by airflow or machinery within ducts, ventilation systems, and industrial infrastructures. It is not simply a wall or barrier, it is a highly engineered component that absorbs, attenuates, and dissipates sound energy while preserving the performance of the system in which it is integrated.

Traditionally, sound traps are based on two main technologies. Passive solutions rely on acoustic insulation materials that absorb part of the noise, while active noise control (ANC) uses sensors and speakers to generate counter-noise and cancel certain frequencies. Both approaches have their strengths but also clear limitations. Passive traps struggle with low frequencies and require bulky installations. ANC is powerful in theory, but in practice, it consumes significant energy and loses efficiency in complex geometries.

Vibiscus has redefined the industrial sound trap by merging the best of both worlds into a hybrid, electroacoustic system. This new generation of silencers does not merely block or mask sound; it actively transforms the acoustic environment to suppress noise at its source.

The uniqueness of the Vibiscus solution lies in its adaptive acoustic surface. Instead of relying on static absorbers, our system uses a network of microphones and mobile membranes that continuously monitor and adjust to the surrounding sound field.

As air flows through a ventilation duct equipped with a Vibiscus sound trap, the system analyzes the noise spectrum in real time. The membranes then modify their configuration to create a dynamic absorbing surface that captures and dissipates unwanted sound waves. This means the solution is not fixed: it adapts to the evolving conditions of airflow and noise.

Unlike ANC, Vibiscus does not generate additional sound. It does not attempt to mask noise with another noise, which often creates unwanted side effects. Instead, it neutralizes the sound energy directly, making the process more energy-efficient and applicable in environments with complex geometries.

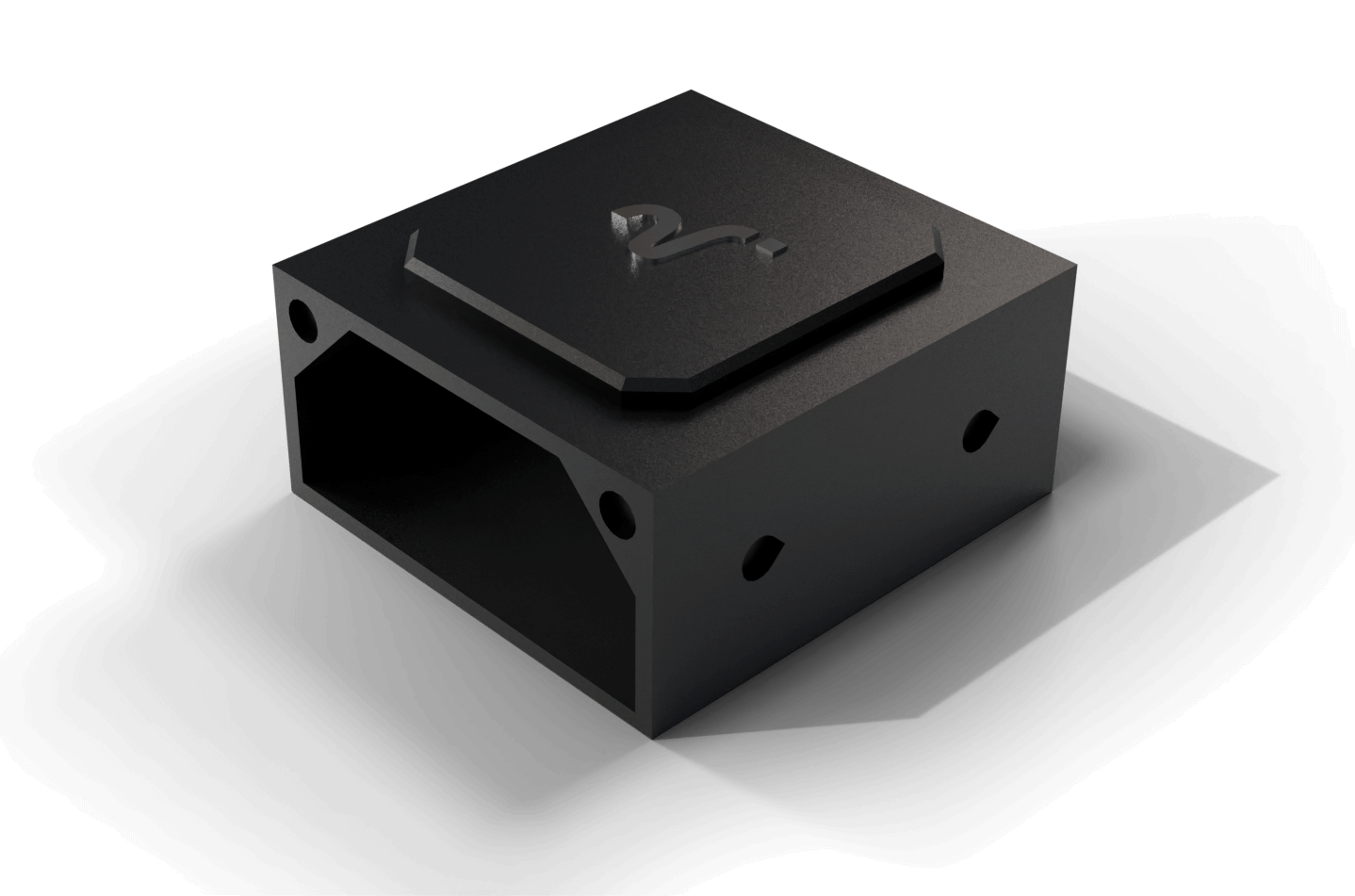

From a practical perspective, our technology is compact and modular, which makes it easier to integrate into existing ducts and industrial systems without requiring a redesign. Whether the installation involves a large ventilation network in a factory or smaller technical rooms, Vibiscus adapts to the specific constraints of each project.

Choosing Vibiscus over conventional sound traps provides tangible benefits for industrial stakeholders.

First, there is the energy efficiency. By avoiding the constant emission of counter-noise, Vibiscus consumes significantly less energy than traditional ANC systems. This translates into both lower operating costs and reduced environmental impact.

Second, our system offers precision through artificial intelligence. The integration of AI allows Vibiscus to fine-tune its acoustic response, ensuring that even fluctuating or unpredictable noise levels are effectively reduced. This precision sets it apart from static, passive materials that can only handle certain frequency ranges.

Another crucial advantage of our technology is its seamless integration. Because the solution is modular and compact, it fits into existing ventilation systems without the need for major modifications. For companies, this means minimal downtime, reduced installation costs, and faster implementation.

From a human perspective, Vibiscus directly contributes to healthier working environments. By reducing exposure to harmful noise levels, it improves worker concentration, lowers stress, and protects long-term hearing health.

Unlike passive absorbers that use fixed materials or ANC systems that emit counter-noise, Vibiscus relies on adaptive membranes controlled by AI. This enables it to absorb and dissipate sound in real time, even in complex duct geometries.

Yes. Vibiscus has been designed to integrate seamlessly into existing installations. Its modular and compact design allows for quick adaptation without major infrastructure changes.

Absolutely. One of the weaknesses of conventional absorbers is their limited impact on low frequencies. Vibiscus, by dynamically adjusting its membranes, can target a wider frequency spectrum, including the low-frequency range that is often the most disturbing.

The solution is versatile and suitable for all sectors where ventilation and ductwork generate noise: manufacturing plants, hospitals, offices, data centers, hotels, and residential complexes.

No. Vibiscus is engineered to maintain efficient airflow. Noise reduction is achieved without compromising ventilation performance, ensuring that comfort and air quality are preserved.

Yes. Between energy efficiency, reduced maintenance, compliance with noise regulations, and improved employee well-being, Vibiscus generates long-term financial benefits.