Noise may be invisible — but in the built environment, its impact is impossible to ignore. It disrupts concentration in open-plan offices, impairs recovery in hospitals, disturbs learning in classrooms, and reduces comfort in residential buildings. In this context, noise control in buildings is not an optional feature. It’s a core element of performance, compliance, and occupant well-being.

And yet, many acoustic problems are not the result of poor materials — they’re the result of late-stage thinking. True acoustic control doesn’t start when complaints begin. It starts on the drawing board.

Whether you’re designing a mixed-use development, retrofitting a hotel, upgrading the acoustic comfort of a commercial space, or managing noise complaints in an industrial facility, noise control must be integrated into the structure, materials, and systems of the building — from day one.

This guide offers a clear, technical, and solution-oriented overview of the principles and practices that govern building acoustics today. From sound transmission class (STC) and absorption techniques to emerging technologies like smart materials and modular acoustic modules, we cover the essential knowledge needed to deliver buildings that are not only functional — but acoustically optimized.

If you’re an architect, engineer, facility manager, or acoustics consultant, this article is for you. Let’s explore how to make buildings that, for once, meet expectations.

10 key factors to consider for an optimal sound control strategy in a building

Factor | What it means | Why it matters |

|---|---|---|

1. Space usage and function | Define the purpose of each area (e.g. office, bedroom, gym, classroom, theater). | Acoustic needs vary: a hotel room needs silence; a concert hall needs diffusion and clarity. |

2. Building layout and adjacencies | Analyze which spaces are next to each other and their acoustic sensitivity | Prevent sound leakage between incompatible zones (e.g. gym above a law office). |

3. Internal noise sources | Identify sound-generating activities: foot traffic, HVAC, conversations, machinery. | Helps isolate, absorb, or redirect sound where it’s produced. |

4. External noise exposure | Measure surrounding noise levels: traffic, trains, bars, airports | Guides facade treatments, window glazing, and entry zone design. |

5. Construction type and material mass | Consider wall types, slab composition, joist systems, and how they transmit sound. | Mass and density directly impact sound blocking and vibration transfer |

6. Floor and ceiling assemblies | Understand the slab/floor system and potential for impact noise. | Important for multi-story buildings where footfall and equipment noise can travel. |

7. HVAC and mechanical system design | Evaluate placement, ductwork, fan types, and potential vibration paths. | Mechanical noise is a frequent complaint and must be addressed at the system level |

8. Privacy requirements | Clarify which areas need speech privacy or confidentiality | Helps define STC goals (e.g., in clinics, HR offices, executive spaces). |

9. Budget and phasing | Determine available resources and whether it’s a new build or retrofit. | Some acoustic upgrades are easier during design; others require phased intervention. |

10. Regulatory and performance standards | Account for local codes (STC, IIC, ISO), LEED, WELL, or client KPIs. | Ensures compliance and avoids future legal or comfort-related challenges. |

Best solutions, materials, and technologies to control sound in 2025

When it comes to acoustic performance, the question isn’t whether to act — it’s how to choose the most effective solution for your context and constraints. Whether you’re designing a school, retrofitting a luxury hotel, or managing acoustics in a mixed-use building, your choices in 2025 are more sophisticated — and more targeted — than ever.

Below is a clear, no-nonsense overview of the top-performing materials and systems used by professionals today, along with their advantages, limitations, and use cases.

Acoustic panels, foams, barriers: pros & cons

First, let’s talk about absorption, reverberation and the related tools. These are particularly useful in environments where clarity, comfort, and ambient balance are essential. Whether you are designing a school, renovating a luxury hotel, or managing the acoustics of a mixed-use building, your choices in 2025 will be more sophisticated and targeted than ever before.

Below is a clear, no-nonsense overview of the top-performing materials and systems used by professionals today, along with their advantages, limitations, and use cases.

Material | Pros | Cons | Ideal use |

|---|---|---|---|

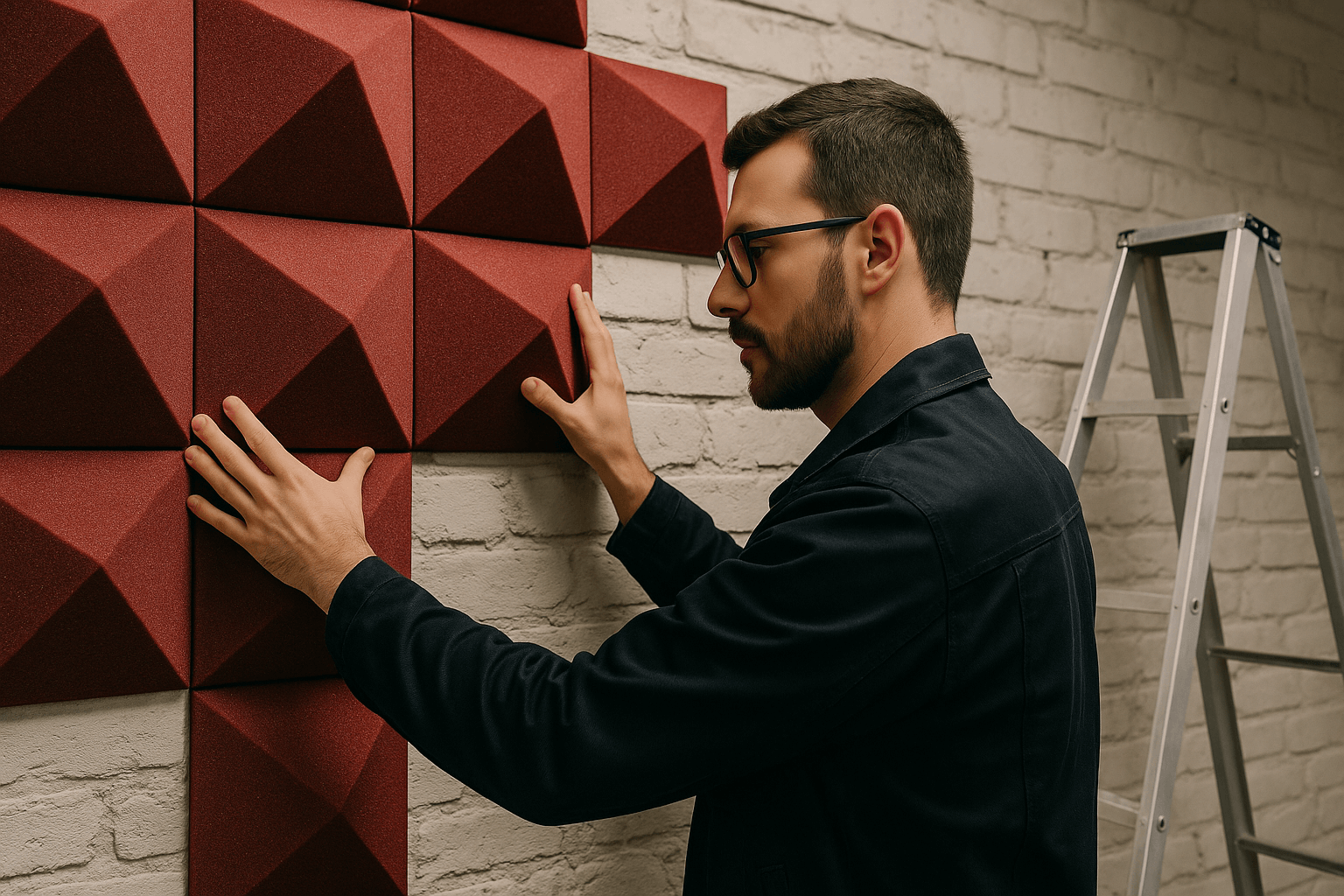

Acoustic wall panels (fabric-wrapped mineral wool or PET) | High NRC values, customizable finish, easy to install | Limited effect on low frequencies | Offices, meeting rooms, classrooms, call centers |

Ceiling tiles (fiberglass, perforated metal with backing | Efficient in large open spaces, fire-rated options | May lack visual appeal if untreated | Commercial buildings, schools, retail stores |

Acoustic foams (polyurethane or melamine) | Lightweight, good for high frequencies, flexible shapes | Poor aesthetics, not fire-rated by default, sensitive to UV | Studios, industrial enclosures, temporary setups |

Acoustic barriers (composite panels or enclosures) | Block airborne noise, modular and rugged | Champ magnétiqueaRequire space, can be heavy or costly | Machinery isolation, noisy service rooms, plant rooms |

👉 Pro tip: Use a hybrid strategy — pairing absorption panels with strategic barriers or blocking assemblies — to simultaneously manage reflection and transmission in the same space.

To learn more about this approach, explore our complete solution for [industrial noise cancellation].

Mass Loaded Vinyl (MLV), double glazing, resilient mounts

These are high-performance solutions for blocking, isolating, and decoupling, especially critical when you’re targeting airborne and structure-borne noise in high-demand environments.

Material | Pros | Cons | Ideal use |

|---|---|---|---|

Mass Loaded Vinyl (MLV) | High STC performance, flexible installation, thin profile | Heavy to handle, more expensive than traditional drywall | Inside walls, ceilings, floors; retrofits or upgrades |

Double glazing / laminated acoustic glass | Excellent external noise blocking, UV and thermal benefits | Adds cost and weight, may require new frames | Façades, urban residential, hotels, executive offices |

Resilient mounts / decoupling clips | Reduce structure-borne transmission, isolate drywall | Requires good detailing and correct spacing | Between drywall and studs, in ceilings or floating floors |

Floating floors (with rubber or cork underlayments) | Excellent IIC ratings, reduce footfall and gym noise | Adds floor height, requires planning and slab compatibility | Multifamily housing, gyms, studios, luxury apartments |

👉 Pro tip: For new builds or high-end projects, layering MLV with double-stud walls and resilient mounts can deliver industry-leading acoustic separation (STC 60+).

🛠 Bonus Insight for 2025

Many professionals in 2025 are turning to programmable acoustic surfaces and smart materials — such as adaptive metamaterials or modulated acoustic panels — for targeted frequency control, dynamic environments, and minimalist integration.

For example, Vibiscus’ modular acoustic system allows professionals to address HVAC noise at the source, reducing the need for bulky treatments and offering programmable updates over time.

What is Sound Control in Buildings? (and why it matters)

Controlling noise in a building is about designing sound with intention. From the hum of HVAC systems to footsteps on an upper floor, every built environment generates sound. The role of acoustic control is to ensure that sound serves the function of the space — not hinder it.

Whether you’re developing an office tower, a school, a healthcare facility, or a shopping center, effective noise control is critical to performance, health, and perception.

Let’s take a closer look at what that actually means.

Professional definition and key principles of noise control

Acoustic control in buildings refers to the strategic integration of architectural design, construction methods, and specialized materials to manage the transmission, reflection, and absorption of sound within and between spaces. Its core objective is to align the acoustic performance of a building with its intended function, regulatory obligations, and user experience expectations.

This discipline addresses two primary goals:

Sound Insulation: Limiting the transmission of airborne and structure-borne noise between zones — such as offices, hotel rooms, or adjacent apartments — and from external sources like traffic or mechanical systems.

Sound Absorption: Controlling reverberation and internal reflections within a space to enhance clarity, speech intelligibility, and acoustic comfort — critical in environments such as classrooms, conference areas, or retail spaces.

To meet these goals, acoustic consultants and building professionals apply four fundamental approaches:

Absorb — Incorporating materials with high sound absorption coefficients (e.g., acoustic panels, ceiling tiles) to reduce unwanted reflections and reverberation.

Block — Designing with mass, density, and airtight construction to prevent sound transmission between zones.

Isolate — Structurally decoupling building elements (e.g., walls, floors, mechanical supports) to prevent vibration transfer.

Diffuse — Using geometric or engineered surfaces to scatter sound energy evenly and eliminate hotspots or echo concentrations.

Each acoustic strategy must be tailored to the operational context.

- A hospital demands discretion and calm.

- A school requires clarity and concentration.

- An office calls for speech privacy without deadening energy.

- An industrial site mandates regulatory compliance and employee safety.

When properly integrated from the earliest stages of planning, acoustic control becomes a performance asset, enhancing occupant satisfaction, reducing complaints, and supporting a building’s long-term functional and commercial value.

The substantial benefits of sound management: comfort, health, compliance

Although unseen on blueprints, poor acoustics have tangible consequences—for occupant well-being, business outcomes, and regulatory compliance.

🔸 Health & Stress

A recent European Environment Agency report estimated that noise pollution contributes to 66,000 premature deaths annually across Europe and significantly increases the risk of heart disease, diabetes, and depression while harming children’s cognitive development.

Chronic exposure to traffic or industrial noise elevates stress hormones, blood pressure, and heart rate, increasing long-term cardiovascular risk .

🔸 Productivity & Cognitive Performance

Studies reveal that background noise can reduce worker productivity by up to 66%—interrupting workflow, increasing errors, and impeding complex mental tasks.

In open-plan offices, 81% of employees reported performance suffering due to noise, with nearly half struggling to concentrate and a third feeling irritated or stressed .

🔸 Comfort, Well-being & Customer Experience

Excessive noise lowers customer satisfaction and shortens visitor dwell times in settings like retail stores, hotels, and restaurants.

A survey of 50,000 workers found that poor speech privacy was the single biggest source of dissatisfaction in office environments.

🔸 Sleep & Recovery

Nighttime noise, even at moderate levels (≥50 dB), disrupts sleep patterns—a key risk factor linked to hypertension and cardiovascular disease.

➡️ Bottom line for Professionals

Noise control is more than a comfort feature—it’s a holistic risk management, health promotion, and performance optimization strategy. For architects, facility managers, and building professionals, acoustic planning at the early design phase reduces retrofit costs, enhances occupant outcomes, and supports compliance with standards like STC, NRC, and ISO 3382. Neglect it, and you risk wasted investment, regulatory penalties, and reputational damage.

What Causes Noise Problems in Buildings?

Understanding the origin and transmission path of sound is essential for selecting the right acoustic strategy. Without this diagnostic clarity, even high-performance materials or expensive treatments may fail to deliver the expected results.

Airborne Sound

Airborne sound refers to any noise that travels through the air before encountering a building surface. This includes:

Voices in a neighboring room

TV or music from an adjacent unit

Traffic noise entering through poorly sealed windows

Emergency sirens or barking dogs outside

Mechanical noise from HVAC systems or elevators

These sounds propagate until they hit a surface — like a wall, ceiling, or window — and either get reflected, absorbed, or transmitted through it. In most cases, transmission occurs when insufficient mass, thin assemblies, or air leaks allow the sound to pass.

Example: In a hotel, a guest hearing conversations or a phone vibrating in the adjacent room is experiencing airborne sound leakage due to poor wall assembly or inadequate sealing around service penetrations.

Structure-Borne Sound (a.k.a. Impact Sound)

Structure-borne sound originates when a physical object vibrates a part of the building structure — and that vibration is then transmitted through solid materials, such as slabs, beams, studs, or pipes.

Common sources include:

Footsteps or moving furniture on an upper floor

Water hammer or flushing toilets within shared plumbing stacks

Elevators or HVAC systems mounted directly on load-bearing elements

Industrial machinery or rooftop generators creating low-frequency rumble

Gym weights dropped in a mixed-use commercial building

These sounds are especially challenging because they don’t follow obvious paths. Vibrations can bypass acoustic barriers by “flanking” through structural junctions like floor-wall connections, pipe runs, or ceiling voids.

Example: In a high-end condominium, residents complaining about constant thuds or vibration from a fitness room two floors above are likely experiencing structure-borne noise transmitted through concrete slabs and steel framing.

When the two overlap

In many real-world scenarios, both types of noise interact. A rooftop HVAC unit may emit airborne noise (fan turbulence) while also generating structure-borne vibrations that travel through support beams into office spaces below. Similarly, footsteps can generate both direct impact noise and airborne resonance if the flooring and ceiling assembly lacks decoupling and mass.

If not addressed early during the design or specification phase, these sources can reinforce each other, leading to:

Acoustic complaints from tenants or customers

Costly retrofits that require structural decoupling

Failure to meet building code or LEED acoustic criteria

How to control noise in a building: 4 Fundamental Methods

More than ever, noise control is a matter of selecting the right acoustic strategy for the right sound problem. Whether you’re dealing with reverberation in a conference room or sound leakage between hotel rooms, every situation calls for a targeted combination of techniques.

There are four fundamental methods that professionals rely on to manage sound in buildings:

Absorb, Block, Isolate, and Diffuse. Let’s see with the 4 most commonly applied approaches in both commercial and institutional environments.

Absorption

(e.g., acoustic panels, ceiling tiles, hanging baffles)

Absorption is the process of reducing unwanted reverberation and echo within a space by introducing porous, sound-absorbing materials that capture airborne sound energy.

When sound hits a hard surface — glass, concrete, wood — it reflects back into the room, compounding noise and reducing clarity. In contrast, absorptive materials convert part of that sound energy into heat, rather than allowing it to reflect.

This technique is especially vital in spaces where speech intelligibility, acoustic comfort, or ambient control are critical.

📍 Common applications:

Classrooms, lecture halls, and training centers

Open-plan offices and meeting rooms

Restaurants, hotel lobbies, and retail stores

Industrial control rooms or mechanical spaces with hard surfaces

🧰 Materials used:

Mineral wool or fiberglass panels wrapped in fabric

Suspended ceiling tiles with high NRC ratings

Acoustic clouds, banners, or wall baffles

Perforated wood panels with absorptive backing

📐 Key Metric:

NRC (Noise Reduction Coefficient) — measures how much sound a material absorbs on a scale from 0 to 1 (higher = more absorption). A well-designed office ceiling, for example, should achieve an NRC of at least 0.75.

👉 Absorption is ideal when you want to improve the internal acoustic quality of a space — but it doesn’t stop sound from traveling between rooms.

Blocking

(e.g., mass-loaded partitions, multi-layered walls, dense glazing)

Blocking, or sound insulation, is the technique of preventing sound from traveling from one space to another. It’s primarily used to combat airborne sound transmission — such as voices, traffic noise, or music — that passes through walls, floors, ceilings, or doors.

The core principle of blocking is simple: more mass = better sound resistance. But mass alone isn’t enough — proper sealing and structural design are just as critical.

📍 Common applications:

Between hotel rooms or residential units

Around private offices and conference rooms

Between treatment rooms in clinics or wellness centers

Between noisy service areas and quiet zones

🧰 Blocking methods & materials:

Double or staggered stud wall assemblies with insulation

Mass-loaded vinyl (MLV) sheets within partition layers

Multi-pane acoustic glazing with laminated glass

Solid-core doors with perimeter seals and drop-down thresholds

📐 Key Metric:

STC (Sound Transmission Class) — quantifies how effectively a building element reduces airborne sound transmission. A standard partition wall may rate at STC 35, while a high-performance acoustic wall can reach STC 55+.

👉 Blocking is your go-to method when confidentiality, privacy, or sound containment is required — from patient consultations to executive boardrooms.

Isolation

(e.g., decoupling, resilient mounts, floating floors)

Isolation is the process of physically separating building elements to prevent the transmission of structure-borne sound — that is, sound that travels through solid materials like floors, walls, beams, and pipes. It’s essential when dealing with impact noise (e.g., footsteps, machinery, furniture movement) or vibration from mechanical systems.

Unlike airborne sound, structure-borne noise doesn’t need air to travel — it moves through physical contact points in the building’s structure. Without isolation, these vibrations bypass acoustic barriers and reach distant rooms, sometimes multiple floors away.

📍 Common applications:

Multifamily housing or hotels with complaints of footsteps or dragging chairs from above

Commercial gyms or dance studios above quiet businesses

Industrial facilities with vibrating equipment or rooftop mechanicals

Buildings with elevators, generators, or HVAC units mounted on structural elements

🧰 Materials & techniques used:

Resilient underlayments (rubber, cork, acoustic mats) under flooring systems

Floating floors decoupled from the structural slab using isolators or spring systems

Resilient mounts and anti-vibration pads for HVAC systems, pumps, or appliances

Double-stud wall assemblies or resilient channel systems to isolate walls and ceilings

Ceiling hangers that suspend drywall from vibration-isolated brackets

📐Key Metric:

IIC (Impact Insulation Class) — measures how well a floor/ceiling assembly attenuates impact sound. A good IIC rating for residential or hospitality environments is 60+, though some codes may require less.

👉 Isolation is your go-to strategy when you need to interrupt vibrations at the source, especially in buildings with shared occupancy, lightweight framing, or mechanical noise challenges.

Diffusion

(breaking up sound, not trapping it)

Diffusion is the technique of scattering sound energy in multiple directions to create a balanced and natural acoustic environment. Rather than absorbing or blocking sound, diffusion redistributes reflections evenly throughout a space to prevent hot spots, flutter echo, and unnatural acoustic shadows.

It’s a subtle but essential technique in environments where sound quality and spatial ambiance are as important as sound control — especially where over-absorption would make the room feel too dead.

📍 Common applications:

Music venues, auditoriums, and performance halls

Lecture theatres and conference centers

Worship spaces and cultural buildings

Executive offices or premium retail interiors

Acoustic treatment in recording studios or home cinemas

🧰 Materials & solutions used:

Quadratic residue diffusers (QRDs) and skyline diffusers made of wood or composite

Irregularly shaped architectural surfaces (e.g., angled wood panels, bookshelves)

Custom-designed wall or ceiling structures with intentional scattering geometry

Hybrid panels combining absorption and diffusion, used in flexible environments

📐 Key Metric:

Diffusion Coefficient (varies by frequency and surface type) — while less standardized than NRC or STC, manufacturers often provide lab-tested values for how evenly a surface disperses sound waves.

👉 Diffusion is ideal when you want to preserve liveliness and clarity in a space without introducing harsh reflections or dulling the room. It’s the finishing layer that gives sound its natural texture.

Acoustic Strategies by Building Component: From Walls to Windows

Every surface of a building plays a role in how sound moves — or doesn’t. To control noise effectively, professionals must look beyond generic solutions and address each building element with its own tailored acoustic strategy.

Whether you’re working on a new construction or retrofitting an existing space, this breakdown will guide you through what matters most at every layer of the envelope — walls, windows, doors, floors, and ceilings — with practical, field-tested tactics for better performance.

🧱 Wall sound control

Walls are the first line of defense against both internal and external airborne noise. But not all walls are created equal. High-performance acoustic walls must balance mass, separation, and damping.

New construction strategies:

Use double stud walls with cavity insulation (e.g., mineral wool) for superior STC ratings.

Include resilient channels or isolation clips to decouple drywall from framing.

Integrate mass loaded vinyl (MLV) between layers for added sound insulation without major bulk.

Design staggered stud layouts to break direct transmission paths.

Renovation strategies:

Add additional drywall layers (with Green Glue compound between sheets).

Fill empty cavities with blown-in cellulose or denim insulation.

Apply decorative acoustic panels for a surface-level improvement.

Use acoustic sealants around outlets, edges, and wall perimeters.

📐 Target STC: Aim for STC 50+ in residential and STC 60+ in commercial or confidential spaces.

🪟 Window sound control

Windows are often the weakest link in a wall assembly — and yet essential for light, air, and aesthetics. Strategic design minimizes the trade-off between performance and transparency.

New construction strategies:

Use acoustic laminated glass with plastic interlayers.

Opt for double or triple glazing with asymmetrical thicknesses.

Design window placements away from dominant noise sources (roads, mechanical zones).

Consider fixed windows or limited opening sizes in critical acoustic zones.

Retrofit strategies:

Install acrylic interior window inserts to create a secondary air gap.

Add custom-cut acoustic curtains or shades.

Reseal frames with weatherstripping or acoustic caulk.

📐 Target: Glazing systems should contribute to a combined STC 35–45, depending on exterior conditions.

🚪 Door sound control

Doors are dynamic by nature, which makes controlling sound around them uniquely challenging. Hollow doors and poor seals account for a large portion of sound leaks between spaces.

Best practices:

Use solid-core doors (e.g., MDF or laminated hardwood) instead of hollow-core.

Install door perimeter seals and automatic drop seals under thresholds.

Specify magnetic or compression gaskets in sound-sensitive rooms.

Stagger door placements in corridors to avoid direct sound transmission paths.

📐 Bonus tip: When planning high-performance rooms (e.g., offices, treatment rooms, studios), avoid doors opening directly into high-noise areas like corridors or mechanical spaces.

🕳️ Floor sound control

Floors are responsible for both airborne sound insulation and impact noise mitigation — especially important in multi-story, multi-tenant environments like apartments, hotels, or mixed-use buildings.

Construction-phase strategies:

Use concrete slabs for mass and separation.

Install floating floor systems with resilient underlayments (rubber, cork, or acoustic mats).

Apply acoustic batt insulation in the cavity below the floor.

Retrofit strategies:

Add high-density carpet with padded underlay.

Use interlocking acoustic floor tiles in gyms or offices.

Install anti-vibration platforms for fitness or mechanical equipment.

📐 Target IIC: Aim for IIC 60+ in residential, hospitality, or commercial environments with frequent foot traffic.

🛖 Ceiling sound control

Ceilings aren’t just overhead — they’re a powerful tool for echo control, privacy, and vertical sound isolation.

Optimal approaches:

Use acoustic ceiling tiles (with NRC 0.75+) in open plan offices or healthcare spaces.

Design suspended ceiling systems below structure-borne noise sources (like mechanical floors).

Combine absorption and diffusion elements (e.g., clouds, wood slats with acoustic backing).

For extra performance, double-layer drywall ceilings with insulation above can block both airborne and impact noise.

📐 Bonus use case: In restaurants or atriums, ceilings are a critical location to treat echo without affecting walls or design features.

🔧 Additional elements often overlooked

Even the best acoustic strategy can fail if key architectural weak points are ignored. These elements are often left untreated — yet they account for a disproportionate amount of noise leakage, complaints, and underperformance in acoustic tests.

Ductwork / vents

Why it matters:

HVAC ducts and ventilation grilles often create direct air paths between rooms — allowing noise to travel freely even through otherwise well-insulated walls or ceilings. They also transmit fan noise and mechanical vibrations throughout the building.

Acoustic solutions:

Install lined ductwork with fiberglass or acoustic foam internally.

Use sound attenuators / silencers in long ducts, especially for return air.

Design acoustic plenums or use duct break-outs with baffles.

Avoid placing supply and return vents on opposite sides of the same wall in quiet zones.

Use anti-vibration mounts for mechanical units and duct supports.

📐 Tip: Always coordinate MEP and acoustic teams early. HVAC design is one of the most common failure points in noise-sensitive environments

Electrical outlets

Why it matters:

A single unsealed electrical box in a party wall can drop STC ratings by 10–15 points — especially in lightweight constructions. Sound travels through these gaps like water through a crack.

Acoustic solutions:

Avoid back-to-back outlets in walls separating units or noise-sensitive rooms.

Use putty pads (fire-rated acoustic gaskets) behind outlet boxes.

Seal gaps with acoustic caulk or backer rod.

In new builds, use airtight electrical boxes with built-in acoustic seals.

📐 Tip: Add acoustic sealing to wall switches, data ports, and any penetrations — not just outlets.

Flanking paths

Why it matters:

Flanking paths are indirect transmission routes that bypass your carefully constructed acoustic assemblies. They can occur through floor slabs, ceiling voids, beam connections, or shared cavities — and they often explain why rooms fail post-construction acoustic tests despite “good” specs on paper.

Acoustic solutions:

Use acoustic breaks or isolation strips at wall/floor/ceiling junctions.

Avoid running ducts, plumbing, or cable trays through shared cavities between units.

Install full-height walls to structure, not just to dropped ceilings.

Use floor-to-slab acoustic barriers inside demountable partitions.

Apply flanking strip insulation in floating floor or raised access floor installations.

📐 Tip: In high-stakes projects (hotels, schools, medical), conduct flanking path modeling during the design phase using acoustic simulation tools.

Your best partner for revolutionary noise control: Vibiscus & Silentflow

At Vibiscus, we don’t treat noise control as an afterthought. We engineer it at the source — with Silentflow, our breakthrough technology that combines modularity, adaptability, and precision to eliminate unwanted sound without blocking ventilation or adding counter-noise.

What makes Silentflow™ different?

Our system uses AI to intelligently alter the acoustic impedance of air itself. This creates a programmable, adaptive surface that absorbs targeted frequencies with surgical precision — without sealing off airflow or introducing artificial noise like ANC systems do.

Unlike traditional insulation or active noise cancellation, Silentflow:

✅ Lets air flow, blocks noise

✅ Works in open or semi-open environments

✅ Requires minimal energy to operate

✅ Adapts to specific noise frequencies (HVAC hum, industrial drones, etc.)

✅ Is modular and upgradable — it grows with your needs

✅ Integrates seamlessly into ventilation ducts, industrial systems, or new builds

No white noise. No bulky construction. Just smart silence, designed from the inside out.

Who we work with?

We work mainly with profesionals:

- Public institutions with strict acoustic regulations (healthcare, education, government)

- Industrial operators facing recurring noise complaints

- Architects & acoustic consultants designing high-performance buildings

- Facility managers seeking comfort, compliance, and satisfaction

- Innovators who want noise control to be invisible, integrated, and intelligent

Our mission: Rethinking how we build for silence

Vibiscus was born from 8 years of public research at FEMTO-ST and engineered for the real world. Our vision? Noise control that’s not layered on top — but baked into the building itself. A future where buildings don’t just shelter… they listen, adapt, and protect.

📌 Want to reduce noise without sacrificing design, ventilation, or energy efficiency?

🔗 Discover Silentflow™ → Industrial noise cancellation

📩 Contact our team → Let’s build intelligent silence together

Vibiscus. When silence becomes intelligent

FAQ

Can noise be completely eliminated?

Not entirely — but it can be significantly reduced.

Complete silence is unrealistic in most environments, but with the right design choices, it’s possible to:

Lower noise to imperceptible levels (e.g. <30 dB in hotel rooms or offices)

Create acoustic privacy zones (e.g. STC 50+ walls)

Mitigate both airborne and structure-borne noise

🎯 The goal is comfort and functionality — not absolute silence.

How to dampen sound in an apartment?

Here are practical ways to reduce noise in apartments — especially when renovation is limited:

Use area rugs with thick underlays to absorb impact sound

Install wall-mounted acoustic panels or curtains

Seal gaps around doors and windows with weatherstripping or acoustic sealant

Place bookshelves or wall units on shared walls for added mass

Use white noise machines or sound masking for ambient control

🏢 For renters: most of these upgrades are reversible and affordable.

What are the four principles of noise control?

The four fundamental principles are:

Absorb – Reduce echo and reverb inside a space (e.g., using fabric panels or ceiling clouds).

Block – Stop sound from passing between spaces by increasing wall or floor mass.

Isolate – Break vibration paths using resilient materials (e.g., floating floors, clips).

Diffuse – Scatter sound to improve clarity and reduce hotspots (e.g., wood slats, diffusers).

🧠 A balanced design combines these to match the function of each space.

Is it better to soundproof during construction?

Absolutely. The most cost-effective and high-performing soundproofing happens during the design and construction phase.

At this stage, you can:

Plan room adjacencies to minimize acoustic conflicts

Choose high-STC assemblies from the start

Integrate mechanical isolation into the MEP layout

Save time and money by avoiding retrofits

🏗️ Retroactive fixes are 2–5× more expensive than proactive design.

How can I control noise without renovation?

If you’re working in a finished space or rental, you can still make a big difference:

Add freestanding acoustic partitions or ceiling-hung baffles

Use door sweeps, window inserts, or acoustic curtains

Rely on soft furnishings to reduce echo (rugs, fabric panels, sofas)

Use self-adhesive acoustic foam in studios or small offices

Play ambient background sound (e.g., white noise) to mask intrusions

💡 Perfect for open offices, shared apartments, or coworking spaces.

How do you block out construction noise?

Construction noise is often low-frequency and structure-borne, making it hard to eliminate completely — but here’s how to manage it:

Install double-glazed or laminated windows facing the noise source

Add interior acrylic window inserts

Use mass-loaded vinyl curtains or barriers

Seal window frames and door gaps

Consider white noise to mask transient peaks

📍 For long-term construction near your building, façade upgrades may be worth the investment.

How to stop noise from upstairs to downstairs?

Footstep and furniture noise are usually impact sounds transmitted through the structure. The best solutions include:

Floating floors with acoustic underlayment in the upper unit

Dense ceiling insulation (mineral wool, cellulose)

Resilient channels or sound isolation clips below the upper floor

Acoustic ceiling panels or suspended ceilings in the lower unit

🏡 Pro tip: Coordinate solutions on both levels for the best results.

How to mitigate loud noises?

To mitigate loud noises effectively:

Identify the source – Is it impact, airborne, or mechanical?

Target the transmission path – Walls, floors, ducts, or windows?

Apply layered solutions – Combine blocking, isolation, and absorption.

Use zoning – Physically separate noisy functions (e.g. breakrooms, gyms, kitchens).

📊 In commercial settings, use acoustic modeling to simulate and solve before building.