Among the important criteria for comfort, acoustic comfort is one of the most significant. Constant background noise, whether in a private or professional environment, can quickly become tiresome and a daily burden. HVAC systems play a significant role in this challenge, as they are a major source of noise pollution. So how can we strike the right balance between the need for this equipment and acoustic comfort? Vibiscus presents its latest solution: a sound trap for HVAC systems.

Modern buildings rely on increasingly powerful ventilation systems to ensure adequate air renewal, temperature regulation, and humidity control. These systems are indispensable, but they are also a major source of acoustic discomfort when not properly treated.

The sound emitted by HVAC systems comes from multiple factors:

Even in high-end buildings, these noises can accumulate and create a constant background hum.

The challenge, then, is to find a balance between acoustic comfort and airflow performance. A poorly designed or oversized silencer can restrict air circulation, increasing energy consumption or reducing system efficiency. Conversely, neglecting acoustic treatment altogether can lead to an environment that feels restless and tiring, even when thermal comfort is achieved.

This is precisely where sound traps come into play, and where Vibiscus brings a revolutionary answer with its sound trap for HVAC systems.

A sound trap, sometimes called a silencer or acoustic attenuator, is designed to absorb and dissipate the noise produced by airflow within HVAC ducts. Traditionally, these devices rely on passive acoustic materials such as mineral wool or foam linings, which dampen the sound by converting its energy into heat.

While effective to a certain extent, these conventional traps suffer from several limitations. Their efficiency drops significantly at low frequencies, they occupy substantial space, and their acoustic properties remain fixed, regardless of changes in airflow or operating conditions.

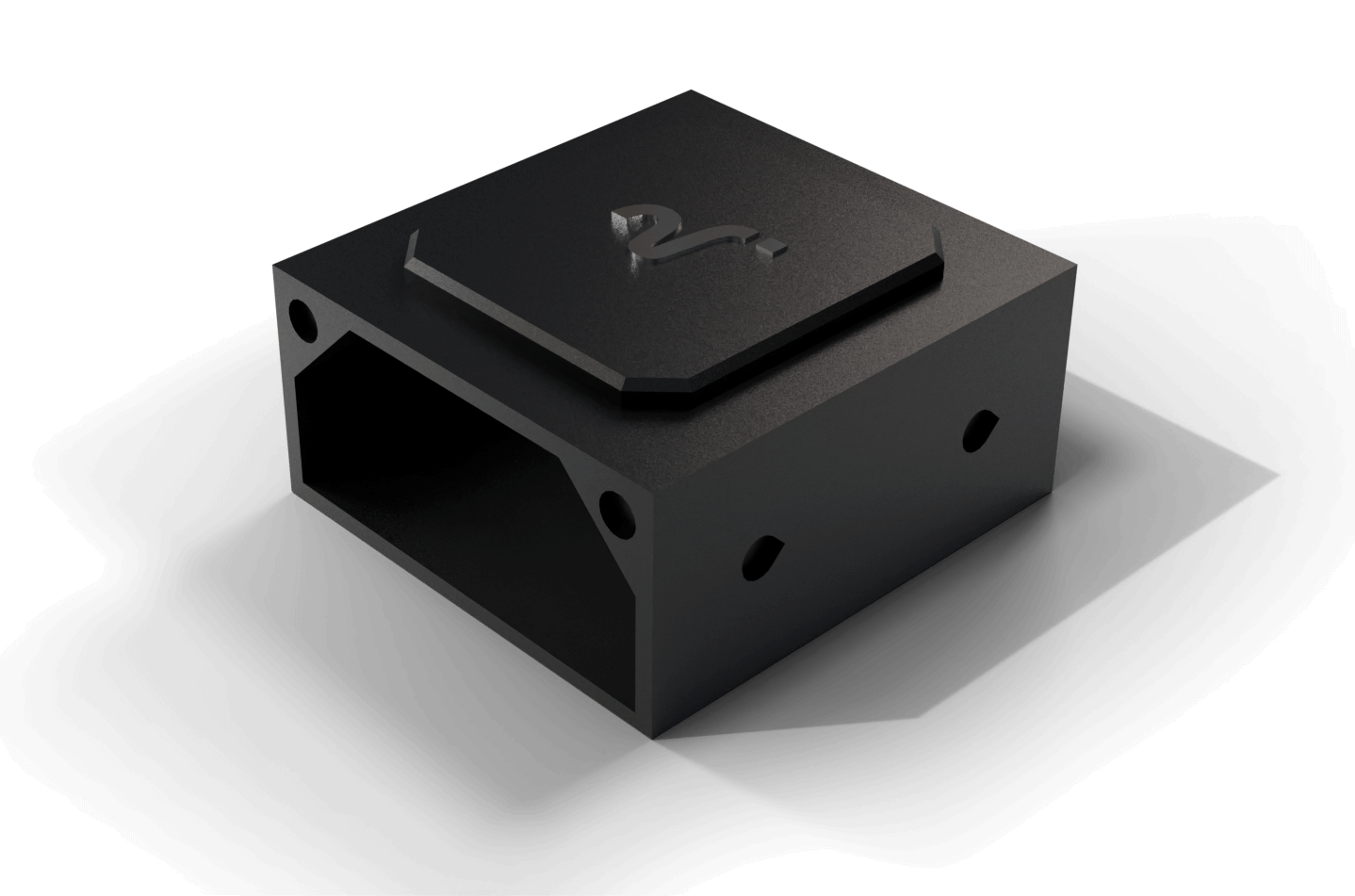

Vibiscus proposes a new generation of sound trap for HVAC systems that is dynamic, intelligent, and far more compact. Instead of passively absorbing noise, the Vibiscus sound trap adapts its behavior in real time. By using an integrated network of microphones and mobile membranes, it monitors the acoustic field inside the duct and modifies the physical properties of the surrounding air. The result is a configurable acoustic surface that can be tuned to target specific frequencies or respond to varying noise conditions.

The key advantage is its energy-neutral operation. Unlike Active Noise Control (ANC) systems, which generate an inverse sound wave to cancel noise, Vibiscus does not emit any counter-sound. Instead, it enhances the air’s ability to dissipate acoustic energy, which is a more stable and sustainable approach, especially in large or geometrically complex ventilation systems.

This technology allows air to flow freely through the ducts while the sound is absorbed at the source. The outcome is a drastic reduction in noise levels without compromising air exchange or system efficiency.

Vibiscus technology represents a new paradigm in acoustic engineering for HVAC systems. Where most existing solutions remain static and material-based, Vibiscus introduces a smart, modular, and AI-assisted sound trap th HVAC systems.

Indeed, Vibiscus operates at the intersection of the two traditional methods of noise control: passive absorption and active cancellation. However, it avoids the drawbacks of both. Rather than adding counter-noise (as in ANC), Vibiscus acts as a “boosted material” that absorbs and dissipates sound more effectively.

Its compact and modular design allows it to be easily integrated into existing ventilation ducts, during construction or retrofitting, without requiring major structural changes.

The Vibiscus system is powered by an artificial intelligence engine that continuously analyzes the noise profile inside the duct. It interprets the data collected by the microphones and commands the membranes to adjust their position or tension, thus altering the surface’s acoustic response. This real-time adaptability ensures that the system remains effective under all conditions.

Traditional silencers rely solely on passive materials to absorb sound. The Vibiscus sound trap, on the other hand, uses an active surface equipped with microphones and membranes that adapt to the acoustic environment in real time. This delivers far greater efficiency, especially at low frequencies, without requiring additional space.

No. The design is optimized to ensure smooth air circulation. Unlike some bulky silencers, the Vibiscus system maintains minimal pressure loss, preserving both air quality and energy efficiency.

Absolutely. Thanks to its compact and modular architecture, it can be integrated into most existing ducts without major modification. This makes it ideal for renovation projects seeking acoustic improvement without system overhaul.

While ANC produces an opposite sound wave to cancel noise, Vibiscus operates differently. It does not add sound, but it modifies the acoustic properties of the air itself to absorb and dissipate noise naturally. This method is more energy-efficient and stable, especially in complex or variable acoustic environments.

Our sound trap for HVAC systems is highly versatile. It can be applied in commercial buildings, offices, hospitals, hotels, residential complexes, research laboratories and industrial facilities. Essentially, any environment where HVAC noise is a concern can benefit from Vibiscus technology.

Our sound trap for HVAC systems developed marks a turning point in the way we approach acoustic comfort in modern buildings. By combining advanced sensing, adaptive materials and AI-driven control, Vibiscus transforms ventilation ducts into intelligent acoustic surfaces capable of listening, understanding, and neutralizing noise at its source. Want to know more? Contact us now.