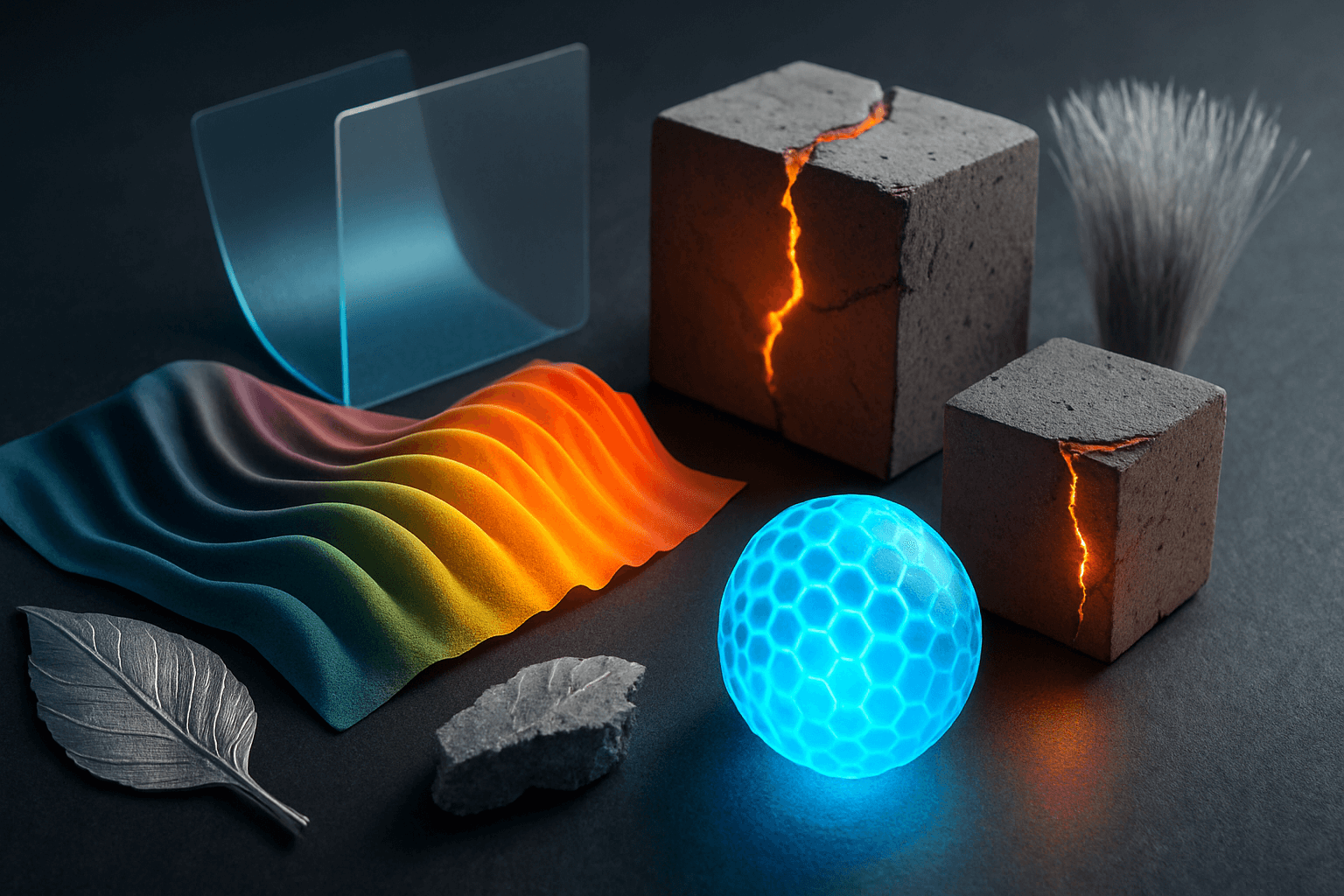

Smart materials are advanced substances capable of sensing changes in their environment—such as temperature, light, or pressure—and responding with a controlled physical transformation, like changing shape, color, or stiffness, making them act like sensors, actuators, or even processors.

Chances are, you’ve already used them in your daily life without even knowing it — and this article aims to shed light on that invisible revolution. To be officially considered a smart material, a compound must undergo a physical transformation when exposed to an external stimulus.

Think of them as materials that react, adapt, and even regenerate — like living organisms. A fabric that opens its pores when you sweat. A wall that muffles noise as soon as it gets too loud. A medical patch that releases just the right dose at just the right time.

Welcome to the world of smart materials — where matter is no longer passive, but interactive, responsive, and intelligent. Take synthetic spider silk: five times stronger than steel and light as a feather, it can cost over $1,000 per gram. Why? Because this material adapts, protects, and performs brilliantly where traditional materials fall short. The most advanced of these compounds can now even process information, blurring the line between matter and machine — a topic more relevant than ever in the age of artificial intelligence.

So this guide is for everyone — whether you’re a designer, engineer, researcher, or simply curious about how these materials are already reshaping our cities, clothes, objects, and ways of life. In short, this is your roadmap to the near future.

Types of Smart Materials (and what makes each one so special)

Material | Caractéristiques principales | Stimulus | Exemple d’utilisation |

|---|---|---|---|

🌀 Shape Memory Alloys | Return to original shape when heated | Heat | Stents, robotics, actuators |

⚡ Piezoelectric Materials | Convert mechanical stress into electricity | Pressure / Vibration | Sensors, lighters, microphones |

🎨 Thermochromic Materials | Change color with temperature | Heat | Mugs, baby spoons, indicators |

🧲 Magnetorheological Fluids | Change viscosity in magnetic field | Magnetic field | Car suspensions, seismic dampers |

🌞 Photoactive materials | React to light (emit / change light) | Light | solar panels, smart windows |

💧 Hydrogels | Swell or shrink based on pH/temp | Electric field | Artificial muscles, soft robotics |

🧬 Electroactive Polymers | change shape when exposed to electricity | Electric field | Artificial muscles, soft robotics |

🧱 Self-healing Materials | Repair themselves after damage | Stress / Dommages | Coatings, composites, asphalt |

🧠 Metamaterials | Engineered for exotic properties | Electromagnetic / Acoustic waves | Invisibility cloaks, antennas |

🍃 Biodegradable Smart Polymers | Eco-friendly & reactive to stimuli | Environment (moisture, light, etc.) | Packaging, agriculture, implants |

Smart Materials, explained with real-life examples

Smart materials are already transforming the way we design, build, and innovate across industries. Below are real-world applications that highlight how smart materials are quietly revolutionizing fields like electronics, fashion, mechanical engineering, civil engineering, and chemistry.

Intelligent Materials in daily life: From Sportswear (fashion) to Smartphones (electronics)

Your running shoes might be smarter than you think. Some high-performance brands now use shape-memory foams that adapt to your stride and return to their original form after each use, improving comfort and support. Thermo-responsive fabrics open micro-vents when you sweat and close when you’re cool — like a built-in climate system.

Meanwhile, your smartphone may already rely on electrochromic glass to auto-adjust brightness, or use piezoelectric sensors in the screen and buttons to translate pressure into commands.

These aren’t lab concepts. They’re everyday realities, quietly improving the devices and products you trust.

In Civil Engineering: Buildings that can breathe (structures)

In civil engineering, smart materials are helping us build safer, more sustainable structures.

Magnetorheological materials are already used in seismic dampers to protect bridges and skyscrapers from vibrations during earthquakes. Their ability to stiffen instantly under a magnetic field makes them ideal for dynamic loads.

Other innovations include self-healing concrete, which seals its own cracks after damage, extending the lifespan of infrastructure while lowering maintenance costs.

Even building facades are evolving — with photoactive coatings that adjust light transmission or color in response to the sun, improving both energy efficiency and visual comfort.

In Mechanical Engineering: Machines that can heal

In mechanical engineering, smart materials are unlocking new levels of performance, adaptability, and safety.

Take piezoelectric materials, for example — used in precision sensors and vibration dampers, they convert mechanical pressure into electrical signals and vice versa. This allows machines to self-monitor, adapt, or trigger automated responses in real time.

Shape-memory alloys are another game-changer: imagine robotic arms or aerospace components that flex and return to their original shape when exposed to heat. These materials reduce mechanical complexity while enhancing flexibility, resilience, and control.

In the field of Chemistry

In the field of chemistry, smart materials are driving breakthroughs in drug delivery, diagnostics, and responsive formulations.

Hydrogels, for instance, swell or shrink depending on pH or temperature — making them perfect for controlled drug release systems that adapt to the body’s needs.

Photoactive compounds are now embedded into everything from smart packaging to UV-sensitive lab materials, while thermochromic dyes change color as a visual signal for chemical reactions or environmental changes.

In chemistry, intelligent materials are active players in how substances behave, react, and communicate in real time.

What most people don’t know about responsive materials

The magic of smart materials often lies in their invisibility. They don’t flash or buzz — they just respond. The anti-fog coating on your glasses, the color-changing strip on a battery, the heat-sensitive mug that reveals a design when filled — all these use smart pigments or thermochromic inks.

Your car’s adaptive suspension system might use magnetorheological fluids, changing stiffness in milliseconds based on the road.

Even scratch-resistant coatings on high-end watches and phones use smart polymers that “heal” micro-abrasions.

We don’t notice them, and that’s the point. Like a good service team at a restaurant, smart materials blend in until they’re needed, making life better without getting in the way.

The benefits of Smart Materials: Why they are the key to a quieter, greener, healthier future

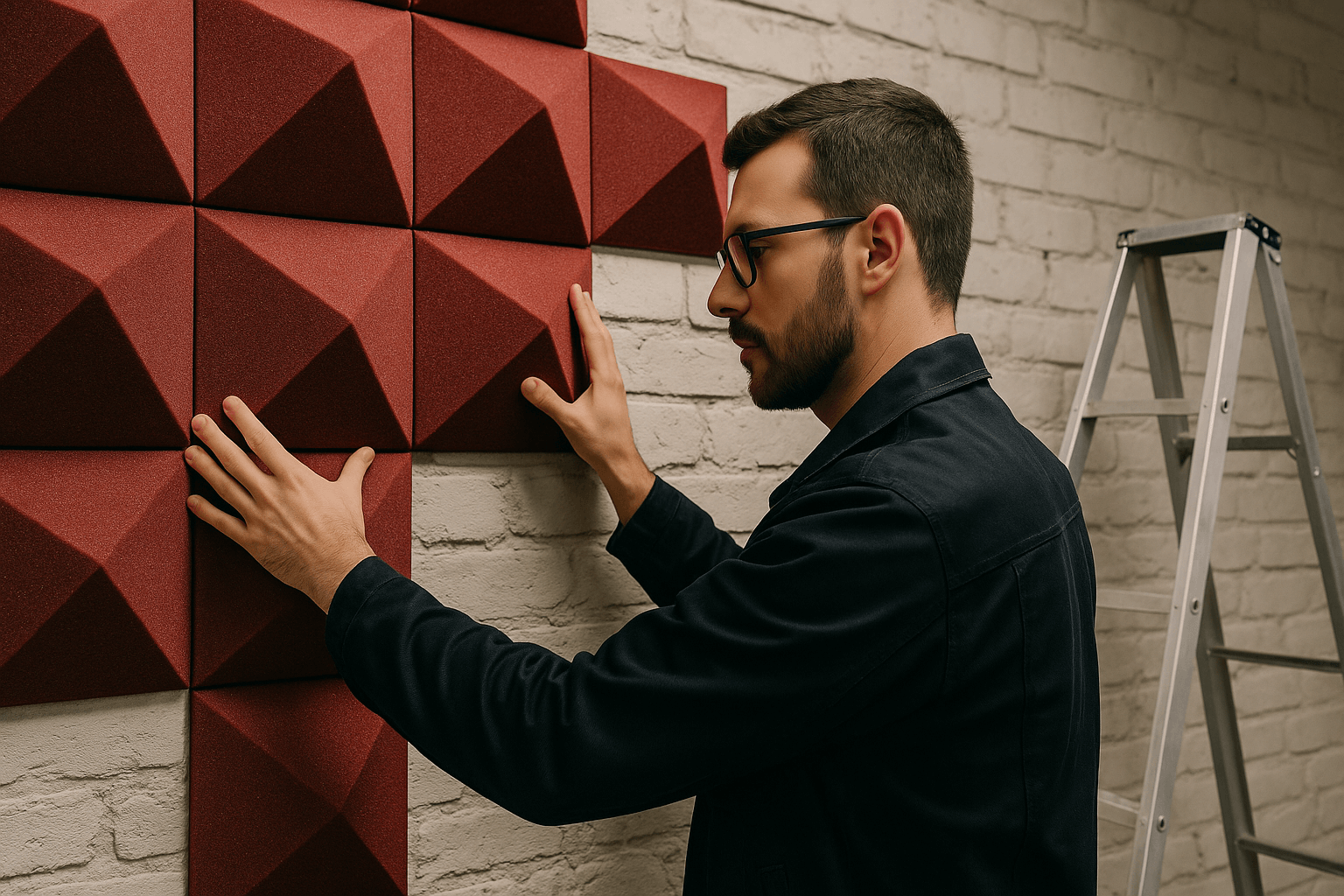

Smart materials are so incredible because they solve common problems encountered by mankind. From reducing stress-inducing noise to building more sustainable cities, these intelligent materials are paving the way for a world that listens, adapts, and protects.

Their impact spans industries, but their benefits all point in the same direction: a future that’s more livable, more responsible, and more connected to the needs of people.

Reducing industrial noise and improving public health

Industrial noise can quickly become a plague. Chronic exposure to high decibel levels has been linked to stress, sleep disruption, cardiovascular issues, and reduced cognitive performance. That’s why smart materials are more than just an acoustic solution — they’re a public health tool.

With programmable acoustic surfaces, vibration-absorbing composites, and materials like those developed by Vibiscus, we can now tackle noise at the source — in ventilation systems, machinery, or HVAC units — creating environments that protect both workers and nearby communities.

Less noise means better focus, safer workplaces, and healthier cities.

Designing sustainable, adaptive, low-impact materials

Most traditional building materials are static and resource-intensive — they consume energy, age poorly, and generate waste.

In contrast, smart materials are designed to adapt. They can react only when needed, making them more energy-efficient, durable, and responsive to the environment.

From biodegradable polymers like Shrilk to self-healing concrete that prevents costly repairs, these materials help reduce our carbon footprint and extend product life cycles.

Even more promising: many smart materials are modular and upgradeable, meaning they evolve over time — not end up in a landfill..

Improving energy efficiency and building performance

Smart materials are transforming the way we build — not just structurally, but energetically. Imagine windows that adjust their opacity with sunlight to regulate indoor temperature, insulating aerogels that cut heating costs in half, or ventilation systems lined with sound-absorbing metamaterials that reduce both noise and energy use.

We’re not talking about nebulous concepts here: they’re already in use. And they’re helping architects, engineers, and cities meet stricter energy regulations while improving comfort and performance.

The future of buildings is interactive, efficient, and alive.

The dark side of Smart Materials: Risks, limits, and ethical questions

Smart materials are transforming the way we build — not just structurally, but energetically. Imagine windows that adjust their opacity with sunlight to regulate indoor temperature, insulating aerogels that cut heating costs in half, or ventilation systems lined with sound-absorbing metamaterials that reduce both noise and energy use.

We’re not talking about nebulous concepts here: they’re already in use. And they’re helping architects, engineers, and cities meet stricter energy regulations while improving comfort and performance.

The future of buildings is interactive, efficient, and alive.

Are all smart materials environmentally friendly?

Not necessarily — and that’s a crucial nuance. While many smart materials aim to reduce energy use or replace less sustainable alternatives, their production processes can be resource-intensive, involving rare metals, synthetic polymers, or chemical treatments.

Some smart coatings or electronics can be difficult to recycle or degrade slowly, leading to e-waste or microplastic concerns. Even biodegradable innovations like Shrilk require specific conditions to decompose effectively.

The solution? Thoughtful lifecycle design — prioritizing modular, upgradeable, or bio-based smart materials, and integrating end-of-life planning from the start.

Surveillance, privacy and unintended uses

When materials can sense, react, or even collect data, privacy becomes a material issue. Imagine walls that detect sound or clothing that tracks motion — technologies that, while helpful, could be repurposed for surveillance without consent.

In public spaces, workplaces, or even homes, the line between functionality and intrusion gets blurry. The real risk isn’t the material — it’s the intent behind its use.

As smart materials become embedded in our environments, ethical frameworks will be essential: Who controls the data? What’s being tracked? Who benefits, and who consents?

Can smart materials fail? Understanding the risks

Yes — and when they do, the consequences can be significant. Smart materials often perform under stress, and extreme heat, pressure, fatigue, or misuse can degrade their functionality.

For example, a shape-memory alloy might lose its “memory” after too many cycles. A self-healing polymer might only regenerate once. And when sensors embedded in structures fail silently, the failure is hard to detect until it’s too late.

That’s why redundancy, testing, and human oversight remain essential. Smart materials aren’t magic — they’re tools, and like any tool, they must be used wisely, monitored carefully, and designed with limits in mind.

Smart Materials: Why they matter right now, and what’s next in 2030, 2040, and beyond

We’re entering an era where matter isn’t just built — it’s programmed. Smart materials are no longer niche lab curiosities; they’re becoming the foundation of next-generation industries, cities, and ecosystems.

From buildings that adapt to their environment to infrastructure that repairs itself and materials that process data like mini-computers, we are witnessing the rise of intelligent matter — and this is just the beginning.

AI-integrated matter and programmable materials

What happens when materials not only respond to stimuli, but learn from them? With the fusion of smart materials and artificial intelligence, we’re looking at a future where surfaces, coatings, and structures become part of the Internet of Things — able to analyze context, predict behavior, and even trigger actions autonomously.

Imagine factory walls that adjust acoustics based on workflow, or road surfaces that redirect energy depending on traffic. The future isn’t passive — it’s programmable, dynamic, and deeply contextual.

4D printing and autonomous manufacturing

3D printing revolutionized fabrication. Now, 4D printing is taking it further — creating smart materials that change shape or function over time, based on how they’re used or where they’re placed.

These materials are designed to self-assemble, evolve, or adapt, without external control. Picture pipelines that expand with heat, furniture that folds itself, or packaging that biodegrades on cue. In the next decades, manufacturing won’t just create objects — it will produce living systems with built-in intelligence.

Vibiscus and the vision of modular, noise-cancelling materials

At Vibiscus, we believe intelligence should be embedded at the source of disruption — not just layered on after.

Our technology, rooted in cutting-edge research from the FEMTO-ST Institute, enables smart materials to modulate the acoustic impedance of air itself, directly where noise is born.

Our system isn’t just passive insulation — it’s a modular, programmable solution for reducing targeted frequencies, adaptable to HVAC systems, industrial machinery, and future urban infrastructure.

That’s why more and more innovators are turning to Industrial noise cancelling — not as an add-on, but as a new standard in how we build, live, and listen.

Why industries, governments, and researchers are betting on them

From climate resilience to workplace well-being, smart materials offer answers to some of the biggest challenges of our time.

Governments invest in them to meet energy and noise regulations, universities study them to redefine physics, and companies adopt them to differentiate and future-proof their offerings.

They represent a rare convergence: sustainability, technology, and adaptability — which is why they’re no longer a “nice-to-have,” but a strategic priority in sectors as diverse as aerospace, healthcare, construction, and public infrastructure.

FAQ

How are smart materials made?

Smart materials are typically created through advanced engineering processes that integrate physical, chemical, or structural responsiveness into their design.

Depending on the material, this may involve embedding particles (like liquid crystals or nanoparticles), using shape-memory alloys, or structuring the material at the micro or nano scale to respond to stimuli.

Increasingly, AI and simulation software are being used to design materials that exhibit highly targeted behaviors — such as vibration damping, thermal regulation, or signal transmission.

Are smart materials expensive?

Smart materials are already present in a wide range of real-world applications, often without being noticed.

They’re used in healthcare (self-healing hydrogels, implants), aerospace and automotive (vibration control, shape-shifting parts), consumer electronics (touch-sensitive screens, piezo sensors), construction (noise-reducing panels, self-repairing concrete), and even in fashion and sportswear (thermo-regulating fabrics).

They’re becoming increasingly mainstream, especially in industries focused on performance, safety, and energy efficiency.

What industries benefit the most from this technology?

Industries that require materials to adapt, endure, or enhance precision are the top beneficiaries. This includes:

- Manufacturing and Industry: for vibration reduction, wear resistance, and acoustic performance.

- Construction and Architecture: for thermal regulation, noise cancellation, and structural health monitoring.

- Medical and Biotech: for drug delivery systems, smart implants, and wound care.

- Transportation: for lighter, stronger, and self-correcting components.

- Consumer Goods: from electronics to smart clothing, where user interaction drives innovation.

Smart materials are increasingly becoming a strategic asset, not just a technical feature.

Can smart materials be recycled or reused?

Sustainability is one of the key challenges in the development of smart materials. While some — like Shrilk or bio-based polymers — are biodegradable or recyclable, others, especially those involving embedded electronics, rare earth metals, or complex composites, can be more difficult to process at end-of-life.

That said, modular design and upgradability (like the approach used by Vibiscus) allow for reusability and software updates, reducing the need to replace entire systems. As awareness grows, researchers are actively working on making smart materials greener, circular, and easier to disassemble or regenerate.

Do smart materials require energy to function?

It depends on the type. Some smart materials are passive — they react naturally to a change in the environment (like temperature or pressure) without external energy input.

Thermochromic inks and hydrogels are good examples. Others are active, meaning they require energy to perform — such as electroactive polymers that need electricity to move or photoactive surfaces that rely on light.

Understanding this distinction is key: passive materials are often more sustainable, while active materials offer greater control and precision.